In these uncertain times, the importance of scientific research that unearths new, valuable information cannot be overstated. A great deal of this research takes place in laboratories.

As such, those facilities should be well-equipped to protect the health of lab technicians and the integrity of their experiments.

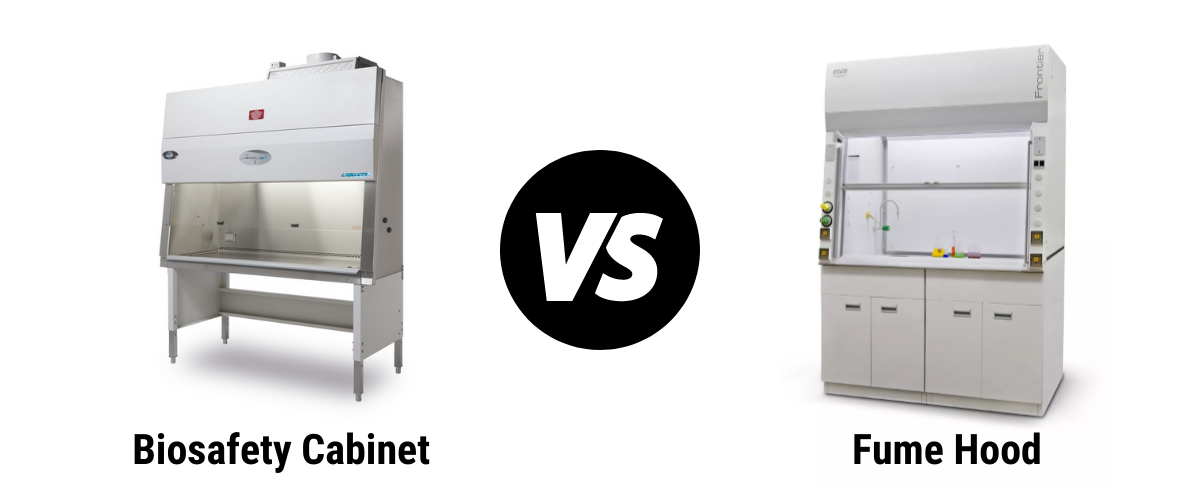

That’s where fume hoods and biosafety cabinets come into play. Fume hoods and biosafety cabinets look similar and both protect the user, but their functions and applications are different.

The main elemental difference between the two is that fume hoods control gases, and biosafety cabinets control particles. The type of materials you are working with are going to determine which type of laboratory hood you will need.

Knowing the level of protection that you require is vital as well, because fume hoods only protect personnel, while biosafety cabinets protect the environment, and the product in addition to protecting personnel. Let’s take a look at the specific differences between fume hoods and biosafety cabinets:

Airflow

Fume Hood

Due to the hazardous nature of the chemicals that pass through fume hoods, air is drawn away from the lab technician beginning at the face of the equipment, across the work surface and through ductwork. It is then diluted and released into the atmosphere. Adequate and continuous airflow is paramount within a fume hood.

Refrain from storing large equipment inside the hood or doing anything that could otherwise disrupt the movement of air in any way within the unit. To ensure a safe and productive work environment, do not put your head inside the hood. Finally, make an effort to keep the sash closed as much as possible.

Biosafety Cabinet

There are three classes of biosafety cabinets and they all have one feature in common: HEPA filtration. High-efficiency particulate air (HEPA) filters are the main difference between biosafety cabinets and fume hoods, and they will effectively trap all known infectious agents, aerosols, particulates, animal dander, and ensure that only microbe-free exhaust air is discharged from the cabinet. Here are the three classes of biosafety cabinets and how they operate:

- Class I

- Air is drawn away from the laboratory worker and across the work surface

- Class II

- Intake air is drawn safely around the operator, sterile air flows downward onto the work surface, and exhaust air is HEPA filtered before it is either recirculated into the laboratory or released into the atmosphere either through ductwork or a canopy connection

- Class III

- Are gas-tight enclosures, with both intake air and exhaust air passing through HEPA filtration

Applications

Fume hoods and biosafety cabinets are better suited to handle different types of materials. Here’s a breakdown of their applications and functions:

- Fume Hoods

- Can be used to handle the following:

- odorous materials

- toxic gases

- reactive materials

- chemicals that can spatter

- aerosols

- carcinogens

- flammables

- other toxic and volatile materials

- Can be used to handle the following:

- Biosafety cabinets

- Provide safety when researching:

- infectious microorganisms

- other hazardous particulates

- Provide safety when researching:

Variations

There are several variations of fume hoods and biosafety cabinets. Here are a few of them:

- Fume Hoods

- By-pass chemical fume hoods

- Most common type of fume hood

- Operate at a constant air volume.

- Auxiliary-air

- Reduced air volume

- High performance fume hoods.

- Operate on a variable air volume (VAV) system

- Are the most efficient.

- Specialty hoods

- Some are particularly suited to handle:

- Perchloric acid (constructed of acid resistant materials)

- Radioactive applications (constructed with additional decontamination features and often require filters in ductwork)

- Some are particularly suited to handle:

- By-pass chemical fume hoods

- Biosafety Cabinets

- Class I

- Have an open front, operate under negative pressure and do not provide product protection

- Class II

- Most common type of biosafety cabinet and is categorized into Types A and B

- Type A

- Recirculate air back into the laboratory, unless they are canopy connected to the outside as required by the application (work with odorous materials)

- Type B

- Are hard ducted to lab exteriors and are suitable for work with only trace amounts of these more toxic substances if required by the microbiological studies being performed within the biosafety cabinet

- Type A

- Most common type of biosafety cabinet and is categorized into Types A and B

- Class I

Recap

Now that you know what the differences are between fume hoods and biosafety cabinets including: how their airflows work, which materials are better suited for each, and the different classes and variations of the two, let’s take a look at a quick rundown of fume hoods and biosafety cabinets:

Fume Hoods

- Used for hazardous chemicals and volatile vapors

- Protects the user

- No HEPA filter

- Exhausts air outside the building

- Not to be used when the sterility of the product is a concern

Biosafety Cabinets

- Used for solid materials and infectious biological agents

- Protects the user, environment, and material

- Must have a HEPA filter

- Does not exhaust air outside, but does remove contaminants

- Not to be used with:

- Volatile or flammable chemicals

- Waste anesthetic gases including isoflurane

Conclusion

With great knowledge comes great responsibility. Scientific research of dangerous chemicals and microbiological organisms is more important now than it has ever been. The correct use of appropriate biosafety cabinets has allowed laboratory technicians and epidemiologists to safely research deadly infectious diseases for years.

In the age of COVID-19, biosafety cabinets have undoubtedly helped to save lives. Finding and implementing the right class of fume hood or biosafety cabinet can make all the difference for your lab and in the world.

Need a Fume Hood or Biosafety Cabinet for Your Lab?

For help finding the right gear for your lab, give us a call at (866) 222-7494 to speak to a lab specialist today!